I don't know the exact reason, but I only received two colors (out of 6 we wanted samples of) this week, but maybe the others didn't make it in time.

It's quite time consuming to clean the molds after usage in order to make a new color, so it's very likely they didn't make it in time for the courier.

No big deal, as I'll visit Greece again soon for the final case tweaks, so I can take the remaining color cases with me then (if I don't receive them until then).

Okay, before looking at the pictures and the video, here are some VERY important informations:

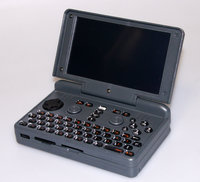

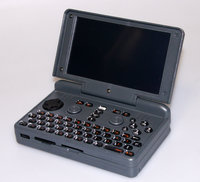

Here are some pictures of the two cases I received. One is gun-metal grey which doesn't look too bad, but for my opinion, it would look better if it's darker.

The second one is a violet one. That's not a color I actually wanted to use, but it was the color one of the Pyra Prototype orderers wanted to get

It will truly be a very unique device

Now some more information about fingerprints and the scratch resistant case.

The best way to describe that is a video.

Here you go:

The packaging

As mass production is coming closer, it's also time to think about the packaging for the device!

The packaging should be nice but as environment-friendly as possible. That's why I'm looking into boxes which are fully made of paper (without foam or plastic) and I also want to get them FSC certified.

We started creating two different packagings so far:

Now it's your turn: Which packaging do you like better?

Vote here at this thread

I hope you liked the news today.

I'll keep you updated as usual.

It's quite time consuming to clean the molds after usage in order to make a new color, so it's very likely they didn't make it in time for the courier.

No big deal, as I'll visit Greece again soon for the final case tweaks, so I can take the remaining color cases with me then (if I don't receive them until then).

Okay, before looking at the pictures and the video, here are some VERY important informations:

- The cases are almost done, but not 100%. So some areas still have some gaps. Don't mind them, they will be gone in the end.

- Especially the front looks bad (with the bent case and a huge gap): This is because the protoype PCB of the CPU board is colliding with the Wifi chip (an edge needs to be cut out there), so that additional height pushes the whole case open. This will NOT happen with the finalized PCBs

- You can see shrinking marks and discolorations on the cases. This is because the mold is not yet hardened and the machine has not been adjusted. Want to know more details? Read the spoiler. Otherwise: Just be assured that the cases will NOT look that ugly when they're finished

So you want to know more about finalizing the mold? Okay

Once everything is physically 100% correct, the steel will be hardened.

That means: It cannot be changed anymore afterwards but it also will not wear out during production (the hard plastic affects the steel as well). It will be a lot more robust.

Because the molds are not yet hardened, you can see some discolorations. They're not fully cleaned yet and the plastic doesn't flow into the mold as good as it should. Also, the temperature is not optimum to not affect the mold too much. This leads to small density issues and therefore also has discoloration.

This will not happen for mass production.

Now about the shrinking marks:

Shrinking marks are areas where parts of the plastic sinks in (most often when there's a peg on the other side), because the weight of the peg pulls the still warm plastic down a bit.

Thinner areas of plastic cool down faster - and so the area with the peg needs longer to cool down and therefore can sink in.

There are various ways to fix that:

As you can imagine, this takes quite a bit of time, so it won't be done before the mold is 100% finalized.

Once everything is physically 100% correct, the steel will be hardened.

That means: It cannot be changed anymore afterwards but it also will not wear out during production (the hard plastic affects the steel as well). It will be a lot more robust.

Because the molds are not yet hardened, you can see some discolorations. They're not fully cleaned yet and the plastic doesn't flow into the mold as good as it should. Also, the temperature is not optimum to not affect the mold too much. This leads to small density issues and therefore also has discoloration.

This will not happen for mass production.

Now about the shrinking marks:

Shrinking marks are areas where parts of the plastic sinks in (most often when there's a peg on the other side), because the weight of the peg pulls the still warm plastic down a bit.

Thinner areas of plastic cool down faster - and so the area with the peg needs longer to cool down and therefore can sink in.

There are various ways to fix that:

- Leaving the plastic piece in the mold for a longer time, until everything is 100% cooled down (this increases the prodution time and therefore the price)

- Change initial temperature of the plastic as this affects the mold flow

- Adjust cool-down termperatures in certain areas (the mold does not have to be evenly cooled down, you can set up the machine to cool certain areas stronger than others)

As you can imagine, this takes quite a bit of time, so it won't be done before the mold is 100% finalized.

Here are some pictures of the two cases I received. One is gun-metal grey which doesn't look too bad, but for my opinion, it would look better if it's darker.

The second one is a violet one. That's not a color I actually wanted to use, but it was the color one of the Pyra Prototype orderers wanted to get

It will truly be a very unique device

Now some more information about fingerprints and the scratch resistant case.

The best way to describe that is a video.

Here you go:

The packaging

As mass production is coming closer, it's also time to think about the packaging for the device!

The packaging should be nice but as environment-friendly as possible. That's why I'm looking into boxes which are fully made of paper (without foam or plastic) and I also want to get them FSC certified.

We started creating two different packagings so far:

- One smaller one where the battery is kept below the Pyra

- One bigger one where the battery and the Pyra are on the same level

Now it's your turn: Which packaging do you like better?

Vote here at this thread

I hope you liked the news today.

I'll keep you updated as usual.

Last edited: