If it was a First Batch screen it was really vibrant compared to the later model screens from my experience.

Actually, we had four or five different throughout the Pandora area, with the last one being my favourite one.

[doublepost=1458399320,1458399042][/doublepost]

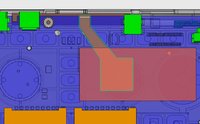

Ha, I knew there were possibilities to reduce the size/weight of that huuuge LCD-PCB.

The size doesn't change, it still supports the LCD at the edges. It will be more like grid (or the Windows logo

) now.

And that's nothing new, we always mentioned there's plenty of space on the LCD PCB for all the parts, so of course there's also plenty of space that can be cut out.

Not sure about the Touchscreen-issues, I never noticed any "grain" on my CC Pandora and it's actualy a very matte screen. My PC Monitor in front of me is also pretty much matte and non reflective and it looks superb. I don't expect alot of issues there on the Pyra screen, I'm sure the final screen will look decent enough. Everything is better than a glossy screen!

Yes, that was also one of the reasons we didn't test that so much (only the accuracy of the LCD, etc.)

I've never seen so much grain on ANY touchscreen so far.

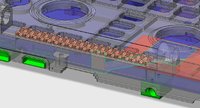

I'm still convinced that there is enough room in the Pyra for a decent cooling solution, the Blend File doesn't include a PCB so I can't see how much space there really is left but I can imagine even a small heatpipe to the outside fit in, if needed.

Depends on what you are planning.

We planned from the very beginning to have some options for heat dissipation / spreading, but we always mentioned we will test how much will be needed when everything is assembled.

I don't think your solution would be much different than one of our options.

In fact, we left enough space between the PCB and the battery compartment to put a full insulation / heat spreading mat inbetween, just in case we need it.