The waiting game still continues, but I've got a quick but tasty update for you

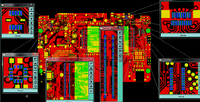

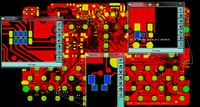

Global Components have populated 24 of the new CPU boards yesterday.

They're still fully untested (GC can't test them), but they're finished and Nikolaus should receive them soon and test them.

Let's cross all fingers that the 4GB RAM will work without any issues

Regarding the mainboards:

It seems like electroinc production is really increasing. The normal wait time of 4 weeks for the bare PCB mainboard has been increased to 8 weeks - and it was the same with multiple companies (GC checked that).

They're all overloaded right now, which increases the production time. Of course, Chinese companies are ALWAYS giving other chinese companies priority in production... but we're not chinese.

Well, they should arrive sometime in May, and together with the CPU board, we can then build final units

Regarding the case:

All changes have been implemented. They're currently updating the 3D files (the ones I have are very old) and will produce a new set which should be finished next week - and hopefully, it's REALLY the final one now.

Next step: Waiting for the case to arrive here and for the mainboards.

So much for the quick news update.

Global Components have populated 24 of the new CPU boards yesterday.

They're still fully untested (GC can't test them), but they're finished and Nikolaus should receive them soon and test them.

Let's cross all fingers that the 4GB RAM will work without any issues

Regarding the mainboards:

It seems like electroinc production is really increasing. The normal wait time of 4 weeks for the bare PCB mainboard has been increased to 8 weeks - and it was the same with multiple companies (GC checked that).

They're all overloaded right now, which increases the production time. Of course, Chinese companies are ALWAYS giving other chinese companies priority in production... but we're not chinese.

Well, they should arrive sometime in May, and together with the CPU board, we can then build final units

Regarding the case:

All changes have been implemented. They're currently updating the 3D files (the ones I have are very old) and will produce a new set which should be finished next week - and hopefully, it's REALLY the final one now.

Next step: Waiting for the case to arrive here and for the mainboards.

So much for the quick news update.