Yay, some news again

And I guess it's mostly good news this time.

Let's just jump straight in!

The hardware

After all the drama we had with the 4GB RAM issue, it seems that this has now found a working solution.

Disabling DLL (delay-locked-loop) made the units run perfectly stable and I could start to work on the tests.

Which means we finally will be able to give feedback about potential production issues to Global Components.

While we're still figuring out what exactly the issue is (we've got a few ideas), it seems this "fix" works without any drawbacks. DLL is basically needed for high frequencies and longer traces (for example, DDR modules in a normal PC), as it synchronizes the timings of the RAM chips. But it could very well be we don't need it, as our RAM chips sit close to the CPU. And after all, we didn't have any more freezes disabling it - and that's what would happen if the timings are not properly synced. So yes, that should be it!

I've done a few Wifi tests and am pretty happy with the final revision of the motherboard.

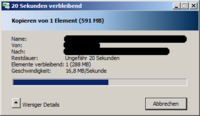

My Wifi Router is in the room above me, so the signal has to pass a floor. And with both 5GHz a 2.4GHz Wifi, I get download speeds of about 4.5 - 4.9MB/s. My laptop manages to get 5.3MB/s for the same download.

So that's pretty good! Pings to google take around 30ms, which is also neat for a mobile device.

So Wifi seems to be fine!

The list of things we need to thoroughly test gets smaller every day.

Now... onto the biggest annoyance right now...

The case

While I receive the latest news on the status of the cases and production from FormAction tomorrow (and lets hope it's not just another set of excuses here), I've visited the Fukuma exhibition in Germany, one of the biggest plastic production fairs out there.

I've met up with Ilias and Dimitri (the two junior bosses of the new company) and we checked for new materials and ideas for plastic production.

There are some interesting things out there!

3M has some silicon glass bubbles which you can add to the material. It makes the material more scratch resistant and also around 25% lighter.

We have no idea yet whether this can be used for the Pyra or not, but it would be interesting.

Also, we've checked out various coatings, as that's basically the only way to make it an AWESOME looking color (like some smooth matte glossy red). It's probably too expensive, but we're checking it out anyways and will get some quotations. It would be a nice addition or we could even make special edition cases for a higher price.

But even without coating, there are quite a few ways to make it properly scratch resistant and nice-looking (just not AWESOME looking).

We'll receive some samples to we can test out various new materials and evaluate them.

Another thing is way more important for me though:

These guys want to help me.

They're both gamers, Ilias is especially annoyed if shoulder buttons are bad, so he wants to make them as good as possible.

Also, they want to improve the design and already have a lot of ideas for that.

Of course, creating completely new moulds is not possible in a short time (exept maybe for the shoulder buttons, as these are small parts), and as you all know we want to start delivery asap.

But as the case is not glued or anything, It can easily be replaced by anybody, especially if it's just the backside with the shoulder buttons and battery (that one can easily be replaced without having to touch the PCB).

So our current plan is this:

That's the current plan, and I'll let you know as soon as I have more news!

And I guess it's mostly good news this time.

Let's just jump straight in!

The hardware

After all the drama we had with the 4GB RAM issue, it seems that this has now found a working solution.

Disabling DLL (delay-locked-loop) made the units run perfectly stable and I could start to work on the tests.

Which means we finally will be able to give feedback about potential production issues to Global Components.

While we're still figuring out what exactly the issue is (we've got a few ideas), it seems this "fix" works without any drawbacks. DLL is basically needed for high frequencies and longer traces (for example, DDR modules in a normal PC), as it synchronizes the timings of the RAM chips. But it could very well be we don't need it, as our RAM chips sit close to the CPU. And after all, we didn't have any more freezes disabling it - and that's what would happen if the timings are not properly synced. So yes, that should be it!

I've done a few Wifi tests and am pretty happy with the final revision of the motherboard.

My Wifi Router is in the room above me, so the signal has to pass a floor. And with both 5GHz a 2.4GHz Wifi, I get download speeds of about 4.5 - 4.9MB/s. My laptop manages to get 5.3MB/s for the same download.

So that's pretty good! Pings to google take around 30ms, which is also neat for a mobile device.

So Wifi seems to be fine!

The list of things we need to thoroughly test gets smaller every day.

Now... onto the biggest annoyance right now...

The case

While I receive the latest news on the status of the cases and production from FormAction tomorrow (and lets hope it's not just another set of excuses here), I've visited the Fukuma exhibition in Germany, one of the biggest plastic production fairs out there.

I've met up with Ilias and Dimitri (the two junior bosses of the new company) and we checked for new materials and ideas for plastic production.

There are some interesting things out there!

3M has some silicon glass bubbles which you can add to the material. It makes the material more scratch resistant and also around 25% lighter.

We have no idea yet whether this can be used for the Pyra or not, but it would be interesting.

Also, we've checked out various coatings, as that's basically the only way to make it an AWESOME looking color (like some smooth matte glossy red). It's probably too expensive, but we're checking it out anyways and will get some quotations. It would be a nice addition or we could even make special edition cases for a higher price.

But even without coating, there are quite a few ways to make it properly scratch resistant and nice-looking (just not AWESOME looking).

We'll receive some samples to we can test out various new materials and evaluate them.

Another thing is way more important for me though:

These guys want to help me.

They're both gamers, Ilias is especially annoyed if shoulder buttons are bad, so he wants to make them as good as possible.

Also, they want to improve the design and already have a lot of ideas for that.

Of course, creating completely new moulds is not possible in a short time (exept maybe for the shoulder buttons, as these are small parts), and as you all know we want to start delivery asap.

But as the case is not glued or anything, It can easily be replaced by anybody, especially if it's just the backside with the shoulder buttons and battery (that one can easily be replaced without having to touch the PCB).

So our current plan is this:

- As soon as the moulds are at the new company, we'll check what needs to be fixed with the cases to make them perfectly usable (mostly the shoulder buttons, probably).

- Depending on the amount of work and time needed, the shoulder buttons will be FULLY remade (only the small parts, not the big mould), as that might be possible within a very short timeframe. Or the current ones will be fixed so they will work.

- After the first case production run, we'll start on improving things. Like the shoulder buttons (if that hasn't happened yet), making the backside of the case thinner (using a sliding battery door) etc.

That's the current plan, and I'll let you know as soon as I have more news!