ExquisiteCorpse

Member

I need more news about the Pyra in my life. It's strange to think I've been following the Pandoras development and now Pyras development since 2008 back when I was debating to get a GPH handheld.

I wouldn't mind some new news as well. Of course, I understand if ED has been too busy with development as of late, since things are coming together quite fast. I think they were going to get a full test unit assembled soon; hopefully when they get to that point they will show it off!I need more news about the Pyra in my life. It's strange to think I've been following the Pandoras development and now Pyras development since 2008 back when I was debating to get a GPH handheld.

My only HDMI sink currently is a monitor, hooked up via an HDMI->DVI adaptor that doesn't split out the audio, so if I used that I'd be plugging bigger speakers in at the same time as getting the video over HDMI.What I'm getting at is how often would a person use the HDMI Out to a much larger display concurrently with headphones plugged into the handheld device(here I'm assuming both cannot be plugged in at the same instance)? Wouldn't they typically use the full sound from the external monitor or, if they absolutely must have bedroom silence and a large screen, plug in their earbuds to the outer display's audio out port?

I'm in a similar situation, I have a DLP projector and while It does have a tiny speaker in it, I need to use another source of sound output on all my devices to bring it to my surround sound system.My only HDMI sink currently is a monitor, hooked up via an HDMI->DVI adaptor that doesn't split out the audio, so if I used that I'd be plugging bigger speakers in at the same time as getting the video over HDMI.What I'm getting at is how often would a person use the HDMI Out to a much larger display concurrently with headphones plugged into the handheld device(here I'm assuming both cannot be plugged in at the same instance)? Wouldn't they typically use the full sound from the external monitor or, if they absolutely must have bedroom silence and a large screen, plug in their earbuds to the outer display's audio out port?

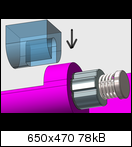

That's quite a neat idea. I was a little confused by the blob covering the end of the hinge axis that's part of the bezel piece until I understood that it's not doing anything to the axis - it's there to stop the lid hinge part (coloured darker in your images) from sliding into the lid under the action of the spring.The bezel part of the new designed Pyra lid (not visible in the sketch) has an notched piece that will slide over the bolt and additionaly holds everything in place when the lid is fully assembled. Imagine the transparent piece is part of the bezel (the black screen cover inside the lid as seen here in ED's sketch) :

Also not visible, the bolt is held in place to the right side within the case of course. The "spring-stop" simply collides with an stop inside the case part so it can only pulled out to the left when the lid is opened. ^^

In theory, the bezel piece could be just flush to the bolt and no axis is sticking out anymore, but I made this more complex design basicly for two reasons: first, it's easier to pull out the hinge piece and second, the axis is longer and can spread the forces a little bit more, in that case also to the screen cover piece. I imagine it is more rigid that way compard to an shorter axis. And the bolt axis can have a little bit of tolerance in there because the actual hinge locks are held in place seperately. (That's the advantage in opposite to the screw-held design where the lenght of the axis must be very precise and must contain a threaded part .)That's quite a neat idea. I was a little confused by the blob covering the end of the hinge axis that's part of the bezel piece until I understood that it's not doing anything to the axis - it's there to stop the lid hinge part (coloured darker in your images) from sliding into the lid under the action of the spring.

Yupp, you are right. The spring tends to push both lock bolts backwards. I imagine it may be a short, tight spring that only works towards the right side and does not push back alot when the mechainsm is in "relaxed" (open) position. However, I also have an solution for this.I see that spring being problematic though. It's in danger of making assembly quite tricky - I'm envisaging it'll be a little different to the Pandora in that you'll align the lid back with the base, then slide the hinge assembly in, then clip in the bezel. That spring's going to be trying to force the hinge back out before you've got the bezel in. I suppose it's there to keep the base part of the hinge (lighter coloured) in contact with the lid piece, and provide resistance as the lid locks in position and is forced out.

The new screen cover bezel ED mentioned could support this mechaism, because ED sayed it is only screwed at the right so it must slide in to the left side first and then closed to the right before fixed. I know that a simple nut (first design) may be the more elegant solution because it will hold the mechaism independent of the LCD cover piece.I wonder now which sides of the bezel are clipped, and which are screwed. It might be easier to concentrate on locking the lid hinge piece in place as you insert the bezel if you didn't have to worry about aligning some clips at the same time.

Well even with nut at the left end, you need somethign to prevent the entire mechanism to just slide out left.I think having the bezel interact with the nut is likely to be awkward. The nut can be in any orientation when it's first inserted. If it's possible to get a nut small enough that there's enough free space around the nut for the bezel to interact with the lid lock piece it might work better.

I'm sure there is a way to have an safe but easily removable clip. Safe hinge mechanism is more important than easy removing imho. But so or so it's all just brainstorming and theory crafting.Your clip solution I've seen before. They're workable, but a bit of a pain to get on and off - perhaps difficult in assembly, and definitely tricky in hackability (since we want people to be able to disassemble the hinge so they can swap the parts about).

Not bad.If the clip part was like this (Forgive bad artistry xD)

clip.png

It would only have to slide into the groove and rotated couterclockwise and then could be held by the bezel.

Then you wouldn't have to worry about it coming loose, and there would be no trouble taking it out because of tight clipping.