TeDaDeS

Forum Addict!

I bought a Home-Assistant (HA) Yellow. It requires a separate purchase of a raspberry pi computer module and an m2 disk.

This weekend I tried installing it but I think the drive is faulty. But the process of installation didn't help, it probably goes fine if it works which is hopefully so for most people.

My process:

I installed the SSD in the HA, the pi was already installed (it's the 4GB RAM version). It's a Samsung disk, some no-label OEM version, but probably 970/980-ish.

I created a micro-SD card with the correct PI image installed on it, via Raspberry Pi Imager with the HA-yellow image. Inserted that in the provided SD-card converter, and that in a SD-USB-adapter. The SD-card bundled converter was faulty btw, so I replaced it with one that I knew was working.

I connected the network cable, SD-USB-adapter (with SD inserted), and powered the unit with the provided power adapter.

The unit booted and I noticed an IP was requested on the router, so the networking was working. I assume installation was happening, the yellow light was blinking but it didn't turn to the long period of blinking (the 5sec on/off). So I just waited until it appeared idling and powered the unit off.

I removed the SD-USB-adapter and powered the unit on again. The unit appears idling and no IP address was requested.

Obviously something was wrong, I didn't know what, so I tried the steps a few times over. I also checked the jumper settings, but those were fine. I also removed the SSD to see if it would improve without, but same result.

I read that if the SSD already had some partitioning on it this issue might happen. But as I don't have some m2 adapter to format the drive, I started the direct installation options.

I switched the boot options by holding both blue/red button for 10sec after powering-on. I also switched jumper from UART to USB, and booted into recovery option.

After installing rpiboot and going through the procedure I was presented with an invalid USB device error in windows. I rebooted my pc and reinstalled the drivers, but same result.

I switched to my Linux box, but turns out that had a full disk. My / had 0 bytes free, causing the desktop to fail to boot. I switched to the terminal view (CTLR+ALT+F1) and removed some files, rebooted into desktop mode and checked why my disk was full.

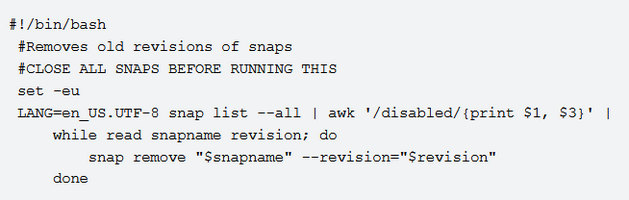

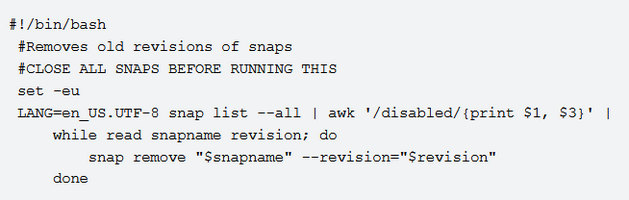

After removing tux kart I had enough free to install my pending updates. I ran apt-get clean and autoremove. I also found some script to remove redundant snap packages, which freed up enough disk space. (https://www.debugpoint.com/clean-up-snap/)

I installed raspberry pi imager and build rpiboot, after already having installed usblib-dev (I installed it first as snap, but that failed on missing libusb).

I got the same result as on the windows box.

Online I see HA yellow / raspberry pi 4 compute doesn't always support all SSD brand/types, which I didn't really expect with using a Samsung disk, so I still hope that part is fine.

I read that a failing usb device-descriptor might happen due to a bad usb-C cable. So I switched to a different higher quality cable, same result.

I realized my raspberry pi 4 compute module doesn't feature the eMMC module, so this procedure might not work.

To make sure the disk is actually found I switch the jumper back to UART and tried connecting to the HA unit with the usb-C cable and using PuTTY. https://yellow.home-assistant.io/guides/use-serial-console-windows/

But no COM port was popping up, turns out the drive of this UART module wasn't recognized (missing driver).

So I searched for the driver on the web, as windows didn't find it, I found it here: https://www.silabs.com/developers/usb-to-uart-bridge-vcp-drivers

After installing this driver I could connect to it on COM3 / 115200 (user=root), don't forget to press Enter to actually see the login screen.

I didn't find any SSD in dmesg / lsblk or /dev/disk/. So I assume that my SSD is faulty.

So I ordered a m2 nvme disk enclosure, so I can check the SSD on a PC. I also ordered a new m2 SSD (one that is claimed to be supported by HA) so I have a working unit.

To be continued...

This weekend I tried installing it but I think the drive is faulty. But the process of installation didn't help, it probably goes fine if it works which is hopefully so for most people.

My process:

I installed the SSD in the HA, the pi was already installed (it's the 4GB RAM version). It's a Samsung disk, some no-label OEM version, but probably 970/980-ish.

I created a micro-SD card with the correct PI image installed on it, via Raspberry Pi Imager with the HA-yellow image. Inserted that in the provided SD-card converter, and that in a SD-USB-adapter. The SD-card bundled converter was faulty btw, so I replaced it with one that I knew was working.

I connected the network cable, SD-USB-adapter (with SD inserted), and powered the unit with the provided power adapter.

The unit booted and I noticed an IP was requested on the router, so the networking was working. I assume installation was happening, the yellow light was blinking but it didn't turn to the long period of blinking (the 5sec on/off). So I just waited until it appeared idling and powered the unit off.

I removed the SD-USB-adapter and powered the unit on again. The unit appears idling and no IP address was requested.

Obviously something was wrong, I didn't know what, so I tried the steps a few times over. I also checked the jumper settings, but those were fine. I also removed the SSD to see if it would improve without, but same result.

I read that if the SSD already had some partitioning on it this issue might happen. But as I don't have some m2 adapter to format the drive, I started the direct installation options.

I switched the boot options by holding both blue/red button for 10sec after powering-on. I also switched jumper from UART to USB, and booted into recovery option.

After installing rpiboot and going through the procedure I was presented with an invalid USB device error in windows. I rebooted my pc and reinstalled the drivers, but same result.

I switched to my Linux box, but turns out that had a full disk. My / had 0 bytes free, causing the desktop to fail to boot. I switched to the terminal view (CTLR+ALT+F1) and removed some files, rebooted into desktop mode and checked why my disk was full.

After removing tux kart I had enough free to install my pending updates. I ran apt-get clean and autoremove. I also found some script to remove redundant snap packages, which freed up enough disk space. (https://www.debugpoint.com/clean-up-snap/)

I installed raspberry pi imager and build rpiboot, after already having installed usblib-dev (I installed it first as snap, but that failed on missing libusb).

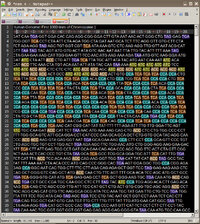

Bash:

sudo apt install git libusb-1.0-0-dev pkg-config build-essential

git clone --depth=1 https://github.com/raspberrypi/usbboot

cd usbboot

make

sudo ./rpibootOnline I see HA yellow / raspberry pi 4 compute doesn't always support all SSD brand/types, which I didn't really expect with using a Samsung disk, so I still hope that part is fine.

I read that a failing usb device-descriptor might happen due to a bad usb-C cable. So I switched to a different higher quality cable, same result.

I realized my raspberry pi 4 compute module doesn't feature the eMMC module, so this procedure might not work.

To make sure the disk is actually found I switch the jumper back to UART and tried connecting to the HA unit with the usb-C cable and using PuTTY. https://yellow.home-assistant.io/guides/use-serial-console-windows/

But no COM port was popping up, turns out the drive of this UART module wasn't recognized (missing driver).

So I searched for the driver on the web, as windows didn't find it, I found it here: https://www.silabs.com/developers/usb-to-uart-bridge-vcp-drivers

After installing this driver I could connect to it on COM3 / 115200 (user=root), don't forget to press Enter to actually see the login screen.

I didn't find any SSD in dmesg / lsblk or /dev/disk/. So I assume that my SSD is faulty.

So I ordered a m2 nvme disk enclosure, so I can check the SSD on a PC. I also ordered a new m2 SSD (one that is claimed to be supported by HA) so I have a working unit.

To be continued...