Is that a Pyra?

Umm... yes...?

Is that a Pyra?

Sorry, I saw the USB port, and thought it was a Mini. I thought maybe it was a Pandora.Umm... yes...?

that is the Micro-HDMI port.Sorry, I saw the USB port, and thought it was a Mini. I thought maybe it was a Pandora.

Well, I'm all kinds of wrong today! XDthat is the Micro-HDMI port.

Make that a 20 minute long 4K ASMR video, pretty please. I need to hear more of those sweet shoulder buttons clicking.this picture is a close up, more high res pyra pron is welcome

this picture is a close up, more high res pyra pron is welcome

I assume that's in a test jig of some sort, because I see no sign of the shoulder buttons yet that's the top of the board we're viewing, and the microHDMI port looks quite a long way from the hole (but then maybe it's an old photo and the positioning wasn't adjusted by then).

Not the lid - though the lid is likely behind it. The plastics there would be the keyboard surround/hinge piece. It is resting on what is/would be the screen/lid. That LCD cable looks like a mock-up and may actually be 'connected' to an actual screen behind/under what we see in the picture.Yes, I can see the switches - I was referring to the keycaps when I said buttons. Maybe that's a pyra case lid, but that seemed unlikely at the time given the LCD cable is connected - but maybe he just wanted to mock it up quickly I guess.

It could be pretty hard getting these through the hinge - and the second problem is that they're probably too wide to fit between the MicroHDMI port and the shoulder buttons.

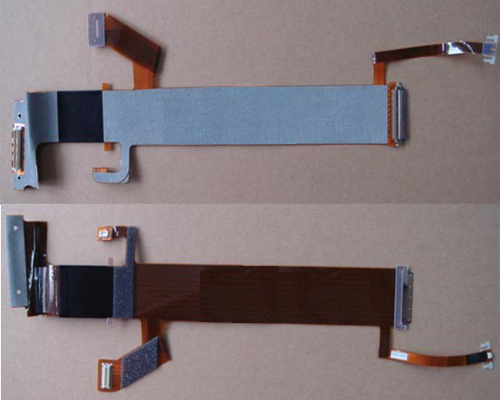

See that picture here:

View attachment 30281

While the connector is wide, the traces themselves don't have a lot of space there.

Not quite accurate. I am very familiar with stranded ribbon cables. They have their uses - and this isn't one of them. This little cable deserves it's engineering. Consider what it is expected to do.The thing is that the wires behave like a flex cable when you want them to fit through a narrow slot, but can be bunched together when you need them to go through a round hole. This eliminates the twisting of tape, and no more hard edges scratch one against another.

Maybe the older ones do, I know for sure that the T4x and T60 series simply use reinforced foil cables, ribbon cables are only being used for the backlight due to its low pin count requirement.IBM Thinkpads use those multistrand flat ribbon cables to connect the screen.

Maybe the older ones do, I know for sure that the T4x and T60 series simply use reinforced foil cables, ribbon cables are only being used for the backlight due to its low pin count requirement.

Slightly bigger photo; still can't see anything. Derp.

It's a plastic covered foil cable, if I had a cam at hand I could open up my T60p for you. Here's some random replacement part picture of the whole T60 cable:Note the gigantic flat cable connecting the base to the screen just left of center.

It's a plastic covered foil cable, if I had a cam at hand I could open up my T60p for you. Here's some random replacement part picture of the whole T60 cable:

The short part to the left connects to the motherboard, it is being fixed by a small metal plate with a rather sharp edge that tends to damage the cable if you're not careful during disassembly.