It won't work like that, that's the problem.

Heat evenly distributes on a heat sink.

Without a heat sink, the SoC might have 110C.

With a 5x5cm heatsink, it might go down to 80C evenly distributed on the heatsink.

With a 10x10cm heatsink, it might go down to 50C evenly distributed on the heatsink.

...stuff about holes in a case and a fan...

Heat distributes evenly into a heat sink - and if it has nowhere to go, does not stop increasing in temp.

The SoC might have 110C at 5 minutes run time.

Using the heat sink it might be 50C at 5 minutes run time - but unless it's transported to the air or hands, it isn't going to stop there. A heat sink alone only draws the problem out longer.

Can you show me a picture of a PC which has a passive heatsink with holes in the case to let out the heat?

The only passive ones I know are simply heatsinks that are fully inside of the device.

Not holes, but I can show you several with heat sinks and external radiators.

http://www.cappuccinopc.com/slimpro-sp675fp_fanless_mini_pc.asp

http://www.logicsupply.com/computers/feature/fanless/

The Shuttle box in this example appears to use vent holes, but likely an aluminum case too:

http://www.makeuseof.com/tag/5-silent-fanless-mini-pcs-that-will-save-you-money/

Um... well, the metal case is irrelevant here, since it uses the case as huge heatsink and the other heatsink doesn't do anything to lead the heat out of the case...?

The case is plastic or plastic with reinforcing fibers right?

Expanded Polystyrene (Coffee Cup) has a thermal conductivity of around 0.03W/m*K

Fibre reinforced plastic has a thermal conductivity of around 0.5W/m*K.

Granite rock is around 2W/m*K.

Aluminum is around 210W/m*K.

Copper is around 390W/m*K.

Diamond is 1000W/m*K.

With all due respect, I think you're completely missing the ideas being presented.

We're talking about using a heat sink that exits the case to be a combined heat sink AND radiator.

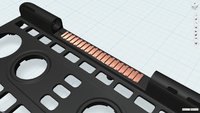

Askarus' idea would have an additional thick layer of copper in/on the main board connected to a copper/air radiant surface hidden in the hinge.

My idea would be to have a thin aluminum heat sink/transport sandwiched between the SoC and the battery that comes out the front of the device under the SD cards and wraps down and back to the battery door. It then has around 10CM^2 of surface area outside of the case to dissipate the heat from the SoC and the battery.

Either idea uses a substance with high thermal conductivity to draw heat into itself and an exposed surface outside of the case to radiate it to the surroundings.

From the mini-table above, you'll notice that aluminum is approximately 800 times better at transporting heat than the case plastics can be. Put another way, 1cm^2 of exposed (out of case) aluminum surface can do a similar job of dissipating heat from the SoC as 800cm^2 of plastic surface area.

Copper doubles that. However without proper sealants it will oxidize and turn green and loose some of it's radiator capacity.

No, we're not going to suggest using Diamond.

The flap/tongue/wrap of aluminum from between the SoC and battery, out the front under the SD slots, then wrapping back around the front edge of the bottom case should yield 5cm by 3cm or 10-15cm^2 of aluminum-air radiator. That's the equivalent of >8,000cm^2 of case plastics or roughly a square surface nearly a meter on a side.

A heat sink grants time - if there is nowhere to let the heat out, that time is limited.

Those holes won't help much, as mentioned before!

The surface outside of the case is too small to have a real effect!

It will probably cool down everything by 1 or 2°C.

Again, I think you're far overestimating the thermal conductivity of case plastics and far underestimating the thermal conductivity of copper and aluminum.

It's orders of magnitude in difference.