Whew, a LOT has happened during the last 10 days!

Mostly good news... so let's start right away!

1. CPU Board Redesign

As you know, Nikolaus worked on improving the vias and decoupling of the CPU Board to finally fix the 1,5GHz issue.

Well, and thanks to a community member, we were able to simulate the outcome so we wouldn't need to produce a new batch just for testing that (which would cost 9000 EUR and take 6 weeks of time).

The community member offered us to do the simulations... and in case you're asking why we couldn't do that ourselves:

The software used does cost about 90k USD... so... yeah

So we're really lucky. Where would we be without the community?

He simulated and compared the old revision and the new one with Nikolaus changes and checked that it fulfills everything that's needed according to the datasheets.

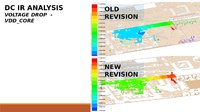

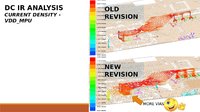

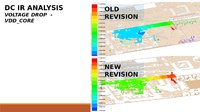

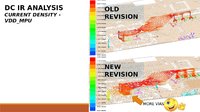

Here are some nice pictures that demonstrate the improvement:

Before someone cries in panic: RED does not mean BAD here.

The target voltage is 1,05V and the color shows how much voltage would be where.

So RED is great, green is okay and the more blue we have, the higher the voltage drop is (which is bad).

Here's a nice summary:

As you can see, while we're not reaching TIs ideal specifications 100%, the boards have been improved A LOT!

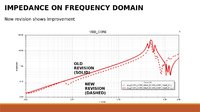

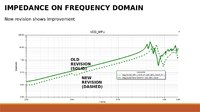

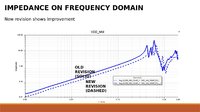

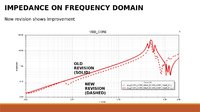

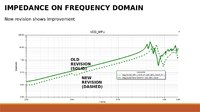

Here you can see the changed impedance of the old and new revision:

Quite a bit of improvement here!

The software can also simulate what happens when you add more capacitors.

We know it's not possible to achieve ideal conditions with that little space we have on our PCB, but that's not needed.

Ideal conditions are just the conditions under which the manufacturer guarantees that the SoC will work for sure.

This is rarely being achieved with such tight PCB designs, but they still work.

Heck, our current CPU Boards work with up to 1,2GHz, and they're MUCH worse than our improved layout.

This improved layout should easily enough to reach the 1,5GHz, but we can probably still squeeze one more capacitor to improve it even further.

So yes, our redesign worked, the possibility to simulate the behaviour was the best that could've happened to us!

Time to produce a few more CPU boards with that new layout - which should definitely be the final one!

2. The keymat

This monday I also received 30 samples of the tweaked keymat.

So, are we there yet?

YES - and no! But that no is not really an issue.

YES: The action buttons and keyboard feels GREAT! They are really nice to press, have a good pressure point.

So yes, the keymat is fine. No need to change it anymore, I really like it.

So what's the no?

You might remember that I decided that the plastic part of the DPad should also be produced by the keymat manufacturer and be glued on top by them.

Well, that plastic part is the first version and is feels great, it has just one minor issue:

The pivot goes down a bit too much. Which means: When you place the keymat onto the table, the pivot already touches the table without you even touching the DPad.

This, of course, makes it feel awkward.

Just using a bit of sandpaper fixed that issue, and for the mass production, it's a minor fix as well.

The most important thing is that the keymat is FINALLY finished! That was a pretty complex part, with all the layers, transparency, etc.

And now it's done - I'm really relieved. One thing less to worry about.

The DPad is a VERY simple part that can easily be changed and even printed with a 3D printer.

3. The mainboards

GC has populated the new prototype mainboards and display boards this Tuesday.

The last thing needed to assemble them to final units are some more cases (I've only got five here) - everything else is here.

So we can assemble multiple units now - and once I receive the next batch of cases, we can assemble 28 prototype units!

Now, some parts are lying around at Nikolaus' place, some at GC, some here... so we need to meet up to assemble everything, I hope we'll find the time for that next week!

4. The displays

800 displays have arrived at Global Components - 230 have been killed by the delivery service (by crushing a box against a wall...)

These will be replaced, of course - and I've asked them whether I could order 500 more... so maybe it's good that this happens

The will be here in time, no worries. We'll need quite a bit of time to assemble the units (a new mass production will always take some time to speed up), and until then, the displays will be here.

5. Quick summary

Pheeww. So, CPU Board should be fixed now. Motherboard and Display board are done as well.

Keymat is finished, just the DPad needs a tiny fix.

Cases are finished except for the wiggling stylus and the too-hard-to-open battery cover.

Displays are finished, touchscreens are perfect.

All electronic parts needed for the mass production are already lying around at Global Components.

We've gotten a LOT closer to the finished Pyra now.

Now I'm hoping for the next case revision and the prototypes... yay!

Mostly good news... so let's start right away!

1. CPU Board Redesign

As you know, Nikolaus worked on improving the vias and decoupling of the CPU Board to finally fix the 1,5GHz issue.

Well, and thanks to a community member, we were able to simulate the outcome so we wouldn't need to produce a new batch just for testing that (which would cost 9000 EUR and take 6 weeks of time).

The community member offered us to do the simulations... and in case you're asking why we couldn't do that ourselves:

The software used does cost about 90k USD... so... yeah

So we're really lucky. Where would we be without the community?

He simulated and compared the old revision and the new one with Nikolaus changes and checked that it fulfills everything that's needed according to the datasheets.

Here are some nice pictures that demonstrate the improvement:

Before someone cries in panic: RED does not mean BAD here.

The target voltage is 1,05V and the color shows how much voltage would be where.

So RED is great, green is okay and the more blue we have, the higher the voltage drop is (which is bad).

Here's a nice summary:

As you can see, while we're not reaching TIs ideal specifications 100%, the boards have been improved A LOT!

Here you can see the changed impedance of the old and new revision:

Quite a bit of improvement here!

The software can also simulate what happens when you add more capacitors.

We know it's not possible to achieve ideal conditions with that little space we have on our PCB, but that's not needed.

Ideal conditions are just the conditions under which the manufacturer guarantees that the SoC will work for sure.

This is rarely being achieved with such tight PCB designs, but they still work.

Heck, our current CPU Boards work with up to 1,2GHz, and they're MUCH worse than our improved layout.

This improved layout should easily enough to reach the 1,5GHz, but we can probably still squeeze one more capacitor to improve it even further.

So yes, our redesign worked, the possibility to simulate the behaviour was the best that could've happened to us!

Time to produce a few more CPU boards with that new layout - which should definitely be the final one!

2. The keymat

This monday I also received 30 samples of the tweaked keymat.

So, are we there yet?

YES - and no! But that no is not really an issue.

YES: The action buttons and keyboard feels GREAT! They are really nice to press, have a good pressure point.

So yes, the keymat is fine. No need to change it anymore, I really like it.

So what's the no?

You might remember that I decided that the plastic part of the DPad should also be produced by the keymat manufacturer and be glued on top by them.

Well, that plastic part is the first version and is feels great, it has just one minor issue:

The pivot goes down a bit too much. Which means: When you place the keymat onto the table, the pivot already touches the table without you even touching the DPad.

This, of course, makes it feel awkward.

Just using a bit of sandpaper fixed that issue, and for the mass production, it's a minor fix as well.

The most important thing is that the keymat is FINALLY finished! That was a pretty complex part, with all the layers, transparency, etc.

And now it's done - I'm really relieved. One thing less to worry about.

The DPad is a VERY simple part that can easily be changed and even printed with a 3D printer.

3. The mainboards

GC has populated the new prototype mainboards and display boards this Tuesday.

The last thing needed to assemble them to final units are some more cases (I've only got five here) - everything else is here.

So we can assemble multiple units now - and once I receive the next batch of cases, we can assemble 28 prototype units!

Now, some parts are lying around at Nikolaus' place, some at GC, some here... so we need to meet up to assemble everything, I hope we'll find the time for that next week!

4. The displays

800 displays have arrived at Global Components - 230 have been killed by the delivery service (by crushing a box against a wall...)

These will be replaced, of course - and I've asked them whether I could order 500 more... so maybe it's good that this happens

The will be here in time, no worries. We'll need quite a bit of time to assemble the units (a new mass production will always take some time to speed up), and until then, the displays will be here.

5. Quick summary

Pheeww. So, CPU Board should be fixed now. Motherboard and Display board are done as well.

Keymat is finished, just the DPad needs a tiny fix.

Cases are finished except for the wiggling stylus and the too-hard-to-open battery cover.

Displays are finished, touchscreens are perfect.

All electronic parts needed for the mass production are already lying around at Global Components.

We've gotten a LOT closer to the finished Pyra now.

Now I'm hoping for the next case revision and the prototypes... yay!