Null

Snug

Because the wife

That's where you're going wrong, you're meant to upload porn of other peoples wives not your own.

Because the wife

Door SLAMS open. Are you winning son?... NOOOOOOOO!That's where you're going wrong, you're meant to upload porn of other peoples wives not your own.

Do you eat animals to get horny? Seems like you might have a few mental issues to sort out.it's your body telling you to not be vegan. listen to it.

Are you winning son?... NOOOOOOOO!

Explain farm animals to me. They're made out of meat too but mainly eat grass (and drink heir mother's milk when young).Everyone was "build" out of flesh, and your Body eats up some parts (like the eat cells who take care that some cells dont grow to much ) so you cant be vegan anyway..

Proteins get recycled indeed. But this recycling does not cause suffering nor does it damage health or the environment. I am not actually vegan anyway, because I still consume stolen bee puke. But I am not buying it anymore. That is my project, stop stealing honey from bees. Stealing honey is much less bad than torturing animals in torture camps, but stealing honey is still pretty mean. Here is another project: finding an good alternative to put in my tea or becoming a real man by getting used to unsweetened tea.Everyone was "build" out of flesh, and your Body eats up some parts (like the eat cells who take care that some cells dont grow to much ) so you cant be vegan anyway..

I just switched to water. I might add flavor to my warm water with herbs. If you really need sweetness in your drink maple syrup works, I used to use raw coconut blossom sugar.Proteins get recycled indeed. But this recycling does not cause suffering nor does it damage health or the environment. I am not actually vegan anyway, because I still consume stolen bee puke. But I am not buying it anymore. That is my project, stop stealing honey from bees. Stealing honey is much less bad than torturing animals in torture camps, but stealing honey is still pretty mean. Here is another project: finding an good alternative to put in my tea or becoming a real man by getting used to unsweetened tea.

Lay down carpet then. Or is your mom strictly against carpet?My Topfield 7160 remote is constantly being dropped on the tiles by She who must be obeyed.

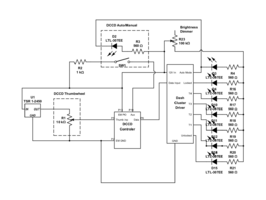

Are you talking about an IR remote control here, or something more specialised., Because I've not found listings for remote control IR codes anywhwere, and the general solution outside of the power button is to put the end of the existing remote up toa learning remote and let it learn it that way. If you don't have a partially working remote I can't see an easy way to reverse engineer it. I assume it has a prefix then the keycode and presumably the prefix is set using pulldown resistors inside the unit, but I have no idea what the keycodes would be.Some time ago I repaired an old audio set I got and I had no remote controller for it. I wanted to have a remote as after an operation with a jigsaw on speakers it started to have a nice sound.

Too lazy to search in Internet and all shops for it.

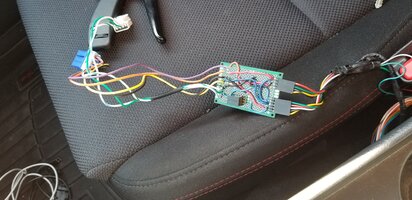

So I found which protocol is used and wrote a Perl script to find commands for every button in the original remote using image analysis and some evolutionary algorithm. Then I made the remote controller program for Arduino. Customized Arduino to run on lower voltage and not use energy when none of 32 buttons of matrix keyboard are pressed. Finally built the remote.

Yes, it was about IR remote. And I had no remote to copy at all.Are you talking about an IR remote control here, or something more specialised., Because I've not found listings for remote control IR codes anywhwere, and the general solution outside of the power button is to put the end of the existing remote up toa learning remote and let it learn it that way. If you don't have a partially working remote I can't see an easy way to reverse engineer it. I assume it has a prefix then the keycode and presumably the prefix is set using pulldown resistors inside the unit, but I have no idea what the keycodes would be.