I don't get it... why do they need a clip?

-God Ginrai

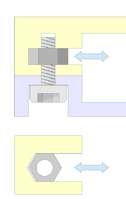

Screw enters from the bottom of the device. Current design is to have it thread into a pillar of plastic on the upper case.

Replacing the pillar of plastic with something metal is a good idea - you get that, right?

In order to have that metal interface it has to anchor to the UNDER side of the upper case plastics and stay put during assembly. Clip on nuts would clip to the plastic (replacing the pillar) and hold-put during assembly and not fall out on the floor.

If standard hex nuts were used - how wold they interface with and hold onto the upper plastics?

More realistically, if this is to be done 'right', plastic (carbon fiber?) pillars should be OK. However, to make a set of reusable threads in soft material, it would be better to machine out a set of coarse and deep threads (thread depth/cut not screw length). Then use a matching screw. Think of a wood/deck screw with the point removed going into a pre-tapped socket.

The Pandora's screws were relatively fine threaded machine screws - not much depth to the thread AND they were expected to self-thread.

Conversely - machine threading the screw holes on every case would probably add $5 to each case. The outcome would be robust, but a tap drilling robot would have to be set up to tap out each screw pillar in the top plastics.