You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are you interested in a new Pandora LCD cable?

- Thread starter Eight Bit

- Start date

hns

Well-Known Member

The problem is twofold. First it is a donation to my company (and not me personally) for developing something (which is not treated as art but engineering service)."incl. German VAT 7/19% unless indicated"

Should I be paying VAT from Norway. I can't claim the tax reduction as a German would…

Grants and donations are often exempt. To me this is a donation for an artistic art project in the interest of the common good.

Edit: Didn't manage to use a company number.

And the second one that there is no physical delivery of goods in this first step.

So there there is no "tax free intra-community delivery" behind. Unfortunate for all of us, but I can't change that

Current status: we already have collected ca. 200€ (and more will come).

Last edited:

Hardcoreufo

Still Fresh

- Joined

- Oct 20, 2016

- Messages

- 11

hns

Well-Known Member

A quick update:

we already have collected 340€ (http://shop.goldelico.com/wiki.php?page=Project Support). Thanks!

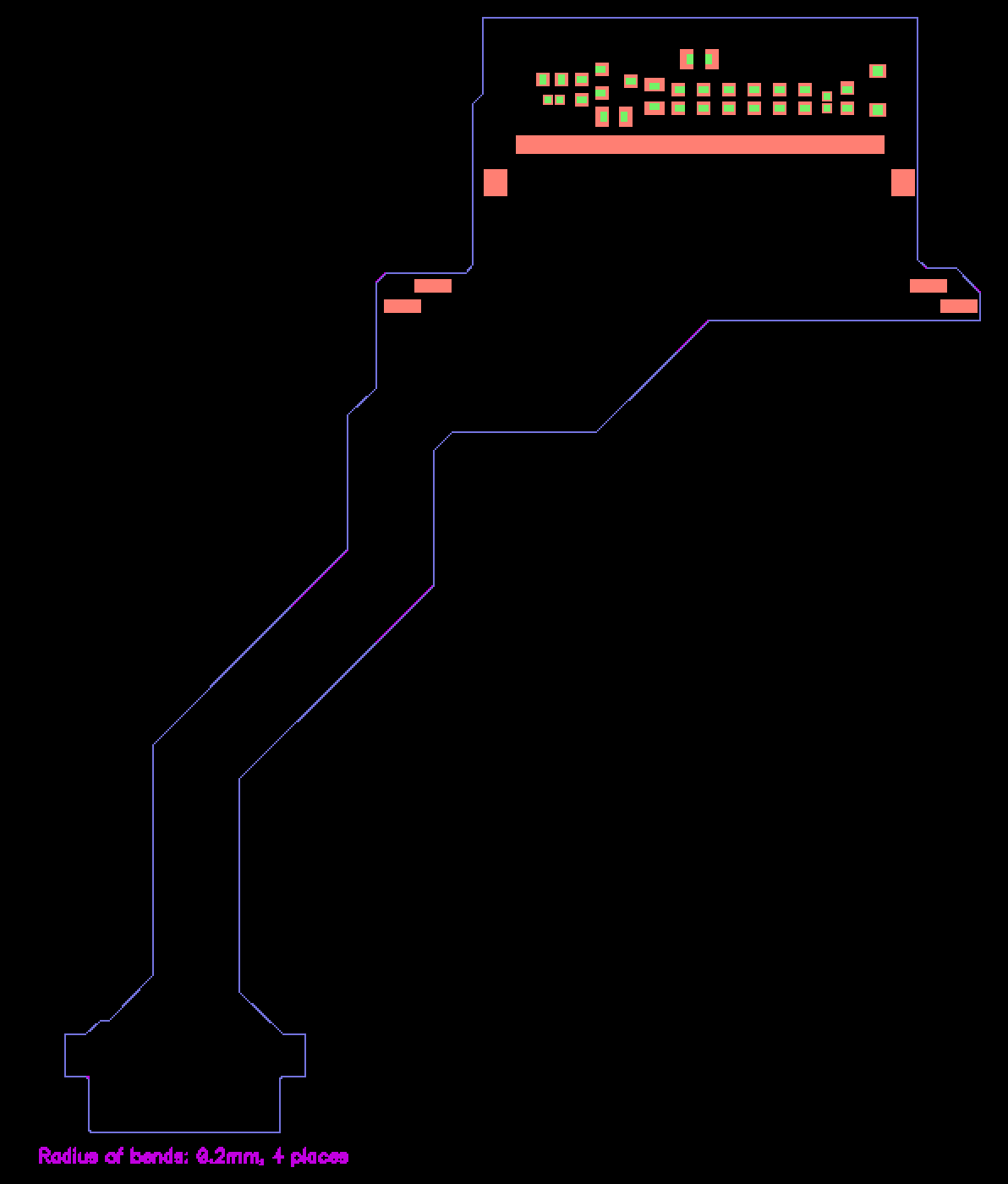

I have in the meantime taken the Gerber files to reconstruct the contour and component position in EAGLE. This makes it easy to get a pick&place program for my machine park.

It also helps to get all required data for a quotation for the let's say first 5 samples.

we already have collected 340€ (http://shop.goldelico.com/wiki.php?page=Project Support). Thanks!

I have in the meantime taken the Gerber files to reconstruct the contour and component position in EAGLE. This makes it easy to get a pick&place program for my machine park.

It also helps to get all required data for a quotation for the let's say first 5 samples.

Last edited:

Eight Bit

Hardcore Member

hns

Well-Known Member

I have not planned to do a full redesign to keep it doable. A full redesign would mean to analyse and rebuild all the copper traces and that is quite difficult and risky - and therefore too expensive for a retrofit project.@hns Is a re-design with an extra connector to seperate the components part from the cable itself out of the question?

So the plan is to use the original Gerber data of the cable for cable production and just create additional data (like component positions and contour) so that the assembly can be easily done.

And, you need the components somewhere anyways. An additional connector would mean that you can plug in the components somehow. The best way would be a second PCB...

Next part in the calculation is that soldering the components is done quite quickly and cost of the components is neglectible. Ca. 2 € if you replace the cable including components. The expensive part is the flexible cable foil. And not even the cable itself but the cost to get someone to setup their production machines. They charge several 100€ before they produce the first cable (hint: we need a little more donations for the first test run...).

Therefore 1 cable is extremely expensive (more than a full Pandora), 10 cables are very expensive, 100 cables are fairly expensive and 1000 are cheap for each one (but total cost is increasing logarithmically so that it would not be cheaper to build 1000 and throw away 900).

levi

Still fresh, damnit!

I wonder if you're planning to supply new speakers with each cable, which IIRC are connected to the set of two tabs on either side of the widest part of the cable? In ED's original disassembly video, he showed a cable without speakers that you needed to solder your old speakers to, but both of the cables I got from ED after my original cable went south had new speakers attached, so I could skip that soldering stage.

comradekingu

Glowing ember

Can https://www.kicad-pcb.org or https://librepcb.org/ be used instead of Eagle?

Anything good on https://www.pcbdirectory.com/manufacturers

Was trying to find one that prints flexible circuit boards close to me that i know about, but couldnt find it.

Those are not repairable though, but waterproof.

Edit: Really hoping the openpandora can be the first project to crowdsource components for an already individually crowdsourced open hardware project.

(That I know about).

Anything good on https://www.pcbdirectory.com/manufacturers

Was trying to find one that prints flexible circuit boards close to me that i know about, but couldnt find it.

Those are not repairable though, but waterproof.

Edit: Really hoping the openpandora can be the first project to crowdsource components for an already individually crowdsourced open hardware project.

(That I know about).

Last edited:

hns

Well-Known Member

Unfortunatley it somethimes happens that WEB links are broken up by e-mail transport.@hns your shop has sent me a link about not completing my payment. However the link provided in the email sends me to page that says: "Not found".

If the link is shown in your mail as multiple lines, please copy them together manually.

And they may be enclosed in < and >. These should not go to the web browser address field.

I hope this helps. Otherwise I can send you the mail in HTML format which is more robust to such problems.

Post automatically merged:

I have neither of these so I simply use what I have. And it is only needed to prepare a good pick&place program for the machine.Can https://www.kicad-pcb.org or https://librepcb.org/ be used instead of Eagle?

We already have Gerber data that has been successfully used.

Edit: Really hoping the openpandora can be the first project to crowdsource components for an already individually crowdsourced open hardware project.

(That I know about).

hns

Well-Known Member

Hm. Strange. I have tried myself and it did work. Can you please just reply to the e-mail (including the mail&link)? This may reveal a not yet known problem in mail transfer of the link.@hns: the link is sound and without the greater than and less than symbols. It's a link that doesn't work. Cutting and pasting reveals it's on a single line.

comradekingu

Glowing ember

hns

Well-Known Member

This is not relevant. AFAIK OpenPandora was and is not open hardware and wasn't designed as such.@hns The motivation is that in the interest of keeping with the openness of the pandora - Kicad is libre software.

Ideally we can have files ready to go for anyone to pick up and use, in a format that isn't proprietary or otherwise requires Eagle.

The LCD cable data I was provided with is Gerber format and the files exist in the public for a long time for pickup by anyone (I seem to be the first one to do something with it). But there is no source code. I even don't know which CAD tool it was created with. So the original cable data for the OpenPandora isn't "libre" in any way.

So I did reconstruct parts of it in Eagle because I am very familiar with it for >10 years.

Next, I do that Eagle work just to create a pick&place program for a proprietary machine that matches the public Gerber data. It is NOT a new cable design. For PCB production I will use the existing Gerber files. There is no plan and need to make these scratchpad files public at all beyond the screen shot shown earlier...

Anyways the Eagle file format is very open. It is XML with a DTD. It is even better documented than the KiCad file format. See for example: https://github.com/p12tic/eagle-brd-merge/tree/master/dtd And there are import tools for almost any CAD system so you don't require Eagle to make use of Eagle files.

Finally I have to shock you: Pyra was also done in Eagle and not KiCad

What I don't like is if people want to impose restriction what tools I should use to solve some task. It is my decision. I always use the one that best fits the task to get things done. And if a tool is libre software doesn't make it automatically superior like a sharper knife. Discussing this also distracts me from getting the task done...

Linux-SWAT

Forum Addict!

- Joined

- Feb 13, 2010

- Messages

- 9,286

The OP became open hardware in 2014.

hns

Well-Known Member

AFAIK, PDF schematics, Gerber data and 3D STL have been made public in a CC-BY-NC-SA like license: https://pyra-handheld.com/boards/threads/the-day-the-pandora-goes-even-more-open.74432/ This does not appear to include easily editable source files from which these printer control files were produced.The OP became open hardware in 2014.

This suffices for my personal opinion what makes hardware open or open enough to develop libre software for it.

But there are semi-official definitions of "open hardware" which also require the source code to be accessible by the public under some open hardware licence and all development tools to be under some open source licence. Within this second view, it is definitively not open hardware.

Anyways, this does not help to get the new LCD cables faster or with less trouble. At the moment it looks as if we have collected enough money for ca. 3 samples with 22 days production time. More money could speed up and/or increase the number of samples. I plan to get a data check and full quotation from the intended flex pcb manufacturer in the next days.

levi

Still fresh, damnit!

I'd hope that given the data comes from a product which has been in the wild now for nearly a decade and improved over time, assuming that data comes from the latest revision, then 3 prototype builds might be enough to get everything sorted for bespoke production.

hns

Well-Known Member

I got confirmation from the manufacturer after they did check the Gerber files. They see no problem.

It will take ca. 20 working days for production of 5 sample PCBs.

I also got a quotation for higher quantities and the 30€ target seems in reach.

So I have placed an order for 5 samples and now I am curious what the result will look like and how it will work!

Unfortunately, there will be nothing to report before 2nd or 3rd April.

And let's cross fingers that there will be no Virus-induced delays.

It will take ca. 20 working days for production of 5 sample PCBs.

I also got a quotation for higher quantities and the 30€ target seems in reach.

So I have placed an order for 5 samples and now I am curious what the result will look like and how it will work!

Unfortunately, there will be nothing to report before 2nd or 3rd April.

And let's cross fingers that there will be no Virus-induced delays.

Similar threads

- Replies

- 40

- Views

- 16K

- Replies

- 8

- Views

- 12K

- Replies

- 4

- Views

- 4K