levi

Still fresh, damnit!

Paperclip? I noticed a bulldog clip, do you perhaps mean that?

Once again almost 2 months later:

So the machine is finished and I have to think about safe transportation to ED since he will be running the tests.

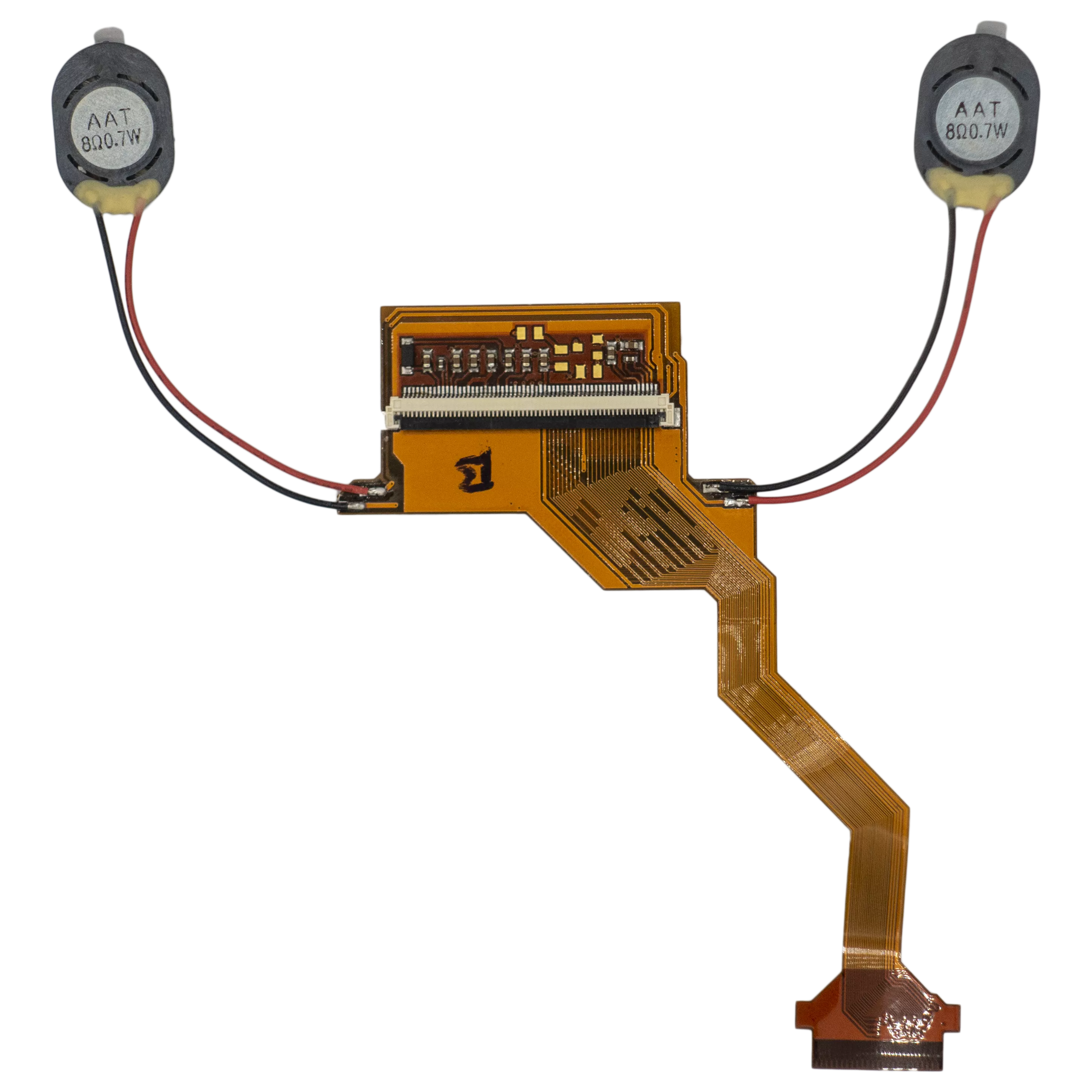

What has not yet been completely elaborated is how to precisely detect that the LCD cable did break and after how many movements.

Well, the counter sows it but someone should sit near the LCD and watch some test image and note the number of cycles.

Or ED makes a video which is taping both the Pandora display and the counter and then the machine can run alone and one looks after it only every 8 hours or so.

If then the cable shows problems, the video can be rewound to the precise location where it started to fail.

Anyways the machine makes ca. 1 movement per second which translates into 60 per minute, 3600 per hour and 86400 per day.

So if we do not need the highest precision it could be run for one hour and then be checked. And then the next hour.

And if there is nobody who can come back after one hour to check the status, the machine is paused and resumed later.

In fact they are already done and shipped to ED... Here are some photos from the production process. And a video is here:Nikolaus is currently populating them, they'll be in the shop soon.

Yes, but still faster than doing everything with 0402 and 0603 SMD by handHaving seen the production speed of the machines at Global Components, this seems to be sooooo slooooooow

But still awesome for sample or small production runs

Did I miss my chance for a cable?