I'm sitting here at Global Components currently doing the Pyra prototype production run.

I already posted some things at Twitter, but I'll do a more comprehensive post here. I will update the first post with the progress we make.

First up, what are we expecting from this pre-production run?

If all goes well, we will have working Mainboards, working Display Boards and working CPU board.

A lot has been tested before with manually populated prototypes, so in theory they should be functional, but we also do this to find issues upfront that could cause problems with the mass production.

Though we can test the basic functions of all the boards here with the equipment Nikolaus has with him, we cannot assemble a unit and test it right away here.

It will need some kernel changes and recompilation, but you can be sure Nikolaus will do that within the next few days so that we should have a fully working setup this week.

Where and how will it be produced?

This is the production line where everything will be produced. The first machine with the dark cover puts the solder paste onto the PCBs. Then the boards move on to two Siemens Siplace machines which automatically populate the boards. They will then be put into a steam solder machine and that's it.

You can only populate and produce one side at once, so the mainboards will need to go through the machines two times.

What you can see here is the part of the machine where all the parts are loaded (it's called the feeder).

Parts will be picked up from here by a head and put onto the PCB.

Most parts come on rolls, like these simcard slots...

... where as some come on trays like the Cinterion 4G modules:

The machine handles both automatically.

Now onto the real thing... the mainboard population.

The first side of the mainboard was populated without any major issues. The frame where the PCBs are in need to be strenghtened a bit, but that's not a big deal.

Good thing we found that out here, as it would've caused delays (and costs) for the mass production run

Here you can see PCBs populated on the first side, waiting inside a tray for the population of the second side:

Here's the second side, already solder paste applied, but waiting for the population:

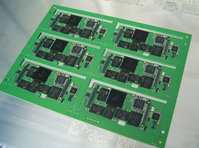

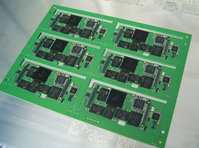

And finally, the second side populated, waiting to go into the steam oven:

Populating the second side of the PCB caused a bit of trouble. You can see clearly how the PCBs are too heavy and hang down in the middle. This is the same issue as mentioned above: The frame needs to be better to support the PCBs. No big change though.

The PCBs has some parts which are VERY close to each other. Combine those two things and the danger exists that they make a short circuit.

That's why a lot on this side of the PCB has actually been populated by hand. Of course, that's not feasible for mass production.

Nikolaus will move some parts a bit so that aren't that close to each other and with the improved frame around the PCBs, everything will be fine.

That is actually not an issue we got here, that's the reason you do a pre-production run: To find out such things and be able to fix and tweak them before the real mass production will start.

Right now, the second side of the PCBs are being soldered. I will update my post here later

UPDATE:

The second side of the PCB has now been populated as well.

We're using a microscope to inspect that all traces look fine and there are no short-circuits:

So far, it looks pretty good.

Nikolaus also connected a USB power source to the Micro-USB port which caused all the Power LED to blink (which means that the battery controller didn't find a battery but is working).

One PCB didn't blink, but the cause was a simple fix: A resistor hasn't been placed properly.

While the second side of the remaining PCBs are being populated, we'll go grab some food (breakfast - didn't have anything today).

It will take a while until we can continue here, as the machine needs to be fed with the new parts for the other PCBs (which will take a while).

UPDATE 2:

We did a first few tests with the mainboard and it seems fine so far.

The LEDs work fine:

Some i2cdetect-tests show that a lot of things are working, but we haven't tested all of them yet, that's a job for Nikolaus for the next few days.

BTW: The keymat in the dark looks beautiful, and that's still with the old keymat (and therefore it will be even better with the updated keymat):

Let's head on to the CPU boards...

Unfortunately, we weren't that lucky with the CPU boards.

Population went fine so far...

... but unfortunately, after it came out from the steam oven, the OMAP5 and the Memory Chips moved around:

So yep, none of those boards is going to work, sadly. (Well, not yet, as they're most probably going to be reworked).

Most probably, the PCB had too much solder paste on - so we need a thinner paste stencil.

Nikolaus was using a thinner one and he soldered his CPU board in the exact same steam oven with the exact same paste, so that's the only thing that has been different.

Unfortunately, it takes 1 - 2 days to get a new stencil, so we can't continue with that today and need to wait a couple of days.

A couple of days is not that much, but it would've been nice to get those finished today, but that's life.

And THAT'S why you do a pre-production run - to find out about all those things and fix them for the mass production run. Luckily, it's not yet anything really bad that went wrong.

The Display boards will be produced tomorrow, as we ran out of time today.

But luckily, that board is not very complex, so I don't expect many issues here.

That's it for today, I'm heading home now and will try to finish the video within the next few days!

I hope you liked my little report while I was here

UPDATE:

Okay, one day has passed and Global Components found the issue with the swimming parts (it was a fault in one of the datasheets).

Nikolaus already grabbed one of the CPU boards which should work fine (they have xrayed it) and is now trying to get it to work (it needs a slightly modified bootloader).

I'll let you know once he got it booting.

And we are lucky: The PCB manufacturer produced more bare PCBs than we needed (in case some were broken) and they all passed the electrical test, so we get some more CPU PCBs. No need to manually rework all of the old one!

In case you haven't seen it in the threads here already:

The new keymats were finished 12 days earlier than planned and are already on the way to me.

The last missing piece now is the case, and I'm currently finding out when that will be finished so I can book a flight to Greece.

I'll keep you posted!

I already posted some things at Twitter, but I'll do a more comprehensive post here. I will update the first post with the progress we make.

First up, what are we expecting from this pre-production run?

If all goes well, we will have working Mainboards, working Display Boards and working CPU board.

A lot has been tested before with manually populated prototypes, so in theory they should be functional, but we also do this to find issues upfront that could cause problems with the mass production.

Though we can test the basic functions of all the boards here with the equipment Nikolaus has with him, we cannot assemble a unit and test it right away here.

It will need some kernel changes and recompilation, but you can be sure Nikolaus will do that within the next few days so that we should have a fully working setup this week.

Where and how will it be produced?

This is the production line where everything will be produced. The first machine with the dark cover puts the solder paste onto the PCBs. Then the boards move on to two Siemens Siplace machines which automatically populate the boards. They will then be put into a steam solder machine and that's it.

You can only populate and produce one side at once, so the mainboards will need to go through the machines two times.

What you can see here is the part of the machine where all the parts are loaded (it's called the feeder).

Parts will be picked up from here by a head and put onto the PCB.

Most parts come on rolls, like these simcard slots...

... where as some come on trays like the Cinterion 4G modules:

The machine handles both automatically.

Now onto the real thing... the mainboard population.

The first side of the mainboard was populated without any major issues. The frame where the PCBs are in need to be strenghtened a bit, but that's not a big deal.

Good thing we found that out here, as it would've caused delays (and costs) for the mass production run

Here you can see PCBs populated on the first side, waiting inside a tray for the population of the second side:

Here's the second side, already solder paste applied, but waiting for the population:

And finally, the second side populated, waiting to go into the steam oven:

Populating the second side of the PCB caused a bit of trouble. You can see clearly how the PCBs are too heavy and hang down in the middle. This is the same issue as mentioned above: The frame needs to be better to support the PCBs. No big change though.

The PCBs has some parts which are VERY close to each other. Combine those two things and the danger exists that they make a short circuit.

That's why a lot on this side of the PCB has actually been populated by hand. Of course, that's not feasible for mass production.

Nikolaus will move some parts a bit so that aren't that close to each other and with the improved frame around the PCBs, everything will be fine.

That is actually not an issue we got here, that's the reason you do a pre-production run: To find out such things and be able to fix and tweak them before the real mass production will start.

Right now, the second side of the PCBs are being soldered. I will update my post here later

UPDATE:

The second side of the PCB has now been populated as well.

We're using a microscope to inspect that all traces look fine and there are no short-circuits:

So far, it looks pretty good.

Nikolaus also connected a USB power source to the Micro-USB port which caused all the Power LED to blink (which means that the battery controller didn't find a battery but is working).

One PCB didn't blink, but the cause was a simple fix: A resistor hasn't been placed properly.

While the second side of the remaining PCBs are being populated, we'll go grab some food (breakfast - didn't have anything today).

It will take a while until we can continue here, as the machine needs to be fed with the new parts for the other PCBs (which will take a while).

UPDATE 2:

We did a first few tests with the mainboard and it seems fine so far.

The LEDs work fine:

Some i2cdetect-tests show that a lot of things are working, but we haven't tested all of them yet, that's a job for Nikolaus for the next few days.

BTW: The keymat in the dark looks beautiful, and that's still with the old keymat (and therefore it will be even better with the updated keymat):

Let's head on to the CPU boards...

Unfortunately, we weren't that lucky with the CPU boards.

Population went fine so far...

... but unfortunately, after it came out from the steam oven, the OMAP5 and the Memory Chips moved around:

So yep, none of those boards is going to work, sadly. (Well, not yet, as they're most probably going to be reworked).

Most probably, the PCB had too much solder paste on - so we need a thinner paste stencil.

Nikolaus was using a thinner one and he soldered his CPU board in the exact same steam oven with the exact same paste, so that's the only thing that has been different.

Unfortunately, it takes 1 - 2 days to get a new stencil, so we can't continue with that today and need to wait a couple of days.

A couple of days is not that much, but it would've been nice to get those finished today, but that's life.

And THAT'S why you do a pre-production run - to find out about all those things and fix them for the mass production run. Luckily, it's not yet anything really bad that went wrong.

The Display boards will be produced tomorrow, as we ran out of time today.

But luckily, that board is not very complex, so I don't expect many issues here.

That's it for today, I'm heading home now and will try to finish the video within the next few days!

I hope you liked my little report while I was here

UPDATE:

Okay, one day has passed and Global Components found the issue with the swimming parts (it was a fault in one of the datasheets).

Nikolaus already grabbed one of the CPU boards which should work fine (they have xrayed it) and is now trying to get it to work (it needs a slightly modified bootloader).

I'll let you know once he got it booting.

And we are lucky: The PCB manufacturer produced more bare PCBs than we needed (in case some were broken) and they all passed the electrical test, so we get some more CPU PCBs. No need to manually rework all of the old one!

In case you haven't seen it in the threads here already:

The new keymats were finished 12 days earlier than planned and are already on the way to me.

The last missing piece now is the case, and I'm currently finding out when that will be finished so I can book a flight to Greece.

I'll keep you posted!

Last edited by a moderator: