Yeah, pin-count can be a pain in the back!

That's why DIP package are ok when you do small projects, but when working on larger ones, it's sometime useful to look at surface mounted packages like TSSOP or QFN. With lot of flux and precision, they're not hard to solder.

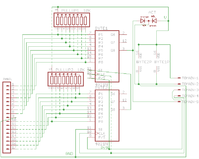

Bit-shifting components are quite useful, as you can serialize a few of them (like in the SNES joypad

2 static shift register used for a 16bit word), the drawback is that you loose speed.

@comradekingu, if you talk about the zikzak, he is still working on it so the B.O.M. might change

At the beginning, I avoided SMD parts like the plague, assuming they would be hell to deal with; but once I learnt the 'drag solder' trick (and the solder-paste hot air gun trick), I realize that SMD parts are _easier_ than DIP in a lot of cases.. if you have a pcboard; ie: if you have a SMD->DIP adaptor (like a TSSOP or SOIC to DIP), then life is easy.. I can solder a 64 or 100 pin chip in a couple minutes, like magic. But if you don't have an adaptor, its quite a PITA .. I've done a few RAMs like thism, soldering 28 or 32 wires to the tiny little legs, and I invariably cook off a few legs or something .. some of these 'low format' SOICs are just a meltable plastic case.. heat for more than a second and its all getting loose :/

Theres a bunch of adaptor makers on the net and on ebay, so you can get a number of common adaptors pretty cheaply (5 bucks each with no pins, say), but some of the better ones are like $15-$20 per unit .. for just a ltitle 2" pcboard! Brutal! You can amke your own for a couple of bucks each on a pcboard, so those guys are going for a killing..

I'm honestly tempted to make up a 50 or 100 sheet of little adaptors, and then sell a bunch on ebay; I can only assume however, that the volume is sufficiently low as to render it not worthwhile.. but who knows

Anyway, I haven't much fear of SMD parts anymore .. I'm using SOIC32 and TSSOP2 SRAM, and I've already got 'in stock' some TQFP64 and TQFP100 avr models; having 64 or 100 pins completely eliminates a lot of the issues you have, makes things much easier. (Hell, with so many pins, don't even need multiplexers, can just have separate whole sets of pins for each chip

.. but again, sort of feels like cheating.

I'm thinking of doing full dip (and SMD with dip adaptors) on the breadboard, like now (will show pics later), but when I get to actually etching out or boardhousing pcboards, I may include half SMD components .. keep size (and costs) down, and fun to solder. However, it also increases your window for error .. a slight measurement problem or whatever, and your pcboard design is not going to solder right or something. (I'm not sure how about tight the solder masks can be made at the low run boardhouses, etc. Still to be researched..)

I sort of enjoy the use of shift registers like SIPO or PISO ones, but they do slow things _way down_, which is something I can't really afford; so I may well just cop out and go to TQFP64 avr8 for my cpu and gpu; I've got adaptors in the mail from Thailand for $5ea, that at least get me to SIP form, and then I can put some right-handle headers on there or something to adapt further to DIP, for prototyping. (Can you imagine.. a TQFP100 chip, with an adaptor to two rows of 50 pins .. that obliterates a lot of space on a breadboard.. like an _entire breadboard_

.. Today is Christmas.. just got 5 parcels in the mail from all over the world. I will take a pic of what I received today

(My wife is very annoyed.. I've been getting 1-3 parcels a week for about 3 months .. most of them are rediculously cheap, but...)

jeff

Maybe have to find myself a stack of Atari 2600 Combat carts or something, to put into Zikzak with some new eproms inside

Maybe have to find myself a stack of Atari 2600 Combat carts or something, to put into Zikzak with some new eproms inside