Pyrate

Member

I guess the title gives a hint already, but I wanted to share with you guys what I did to my brand new GPD WIN Rev 2.

A little Warning upfront: I was very nervous with the installation and especially the keyboard connector is VERY finicky. So only attempt this, if you have some experience with disassembling small integrated electronics.

There are a few videos out concerning the pretty bad thermal solution on the GPD WIN Rev 1, which was using one of those soft thermal pads to bridge the gap between the Atom SoC and the Copper of the Cooling Plate. It was causing the CPU to clock down pretty fast when using on full load.

I had not heard much about the solution used on the Rev 2, only that it was supposed to be a little better.

I can confirm that with a yes and a no. I am sorry to not have taken a picture, but I was probably just taken aback. They simply got rid of the soft thermal pad by using a 1,5 mm thick layer of thermal paste (the artic silver kind). I needed a few minutes to clean that off first...

To not shorten half the board in case it gets somewhere else than on the die, the did use silicon to cover nearby electronics so it kind of works I guess. But I think this is still not such a good way to dissipate the heat.

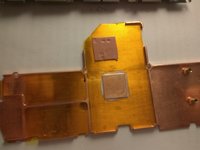

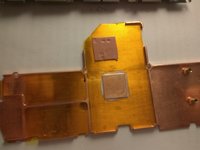

So I used the same method as by Phawx on his youtube guide, by using a 15x15x0,5 mm copper shimming plate (you can get a pack of those for 6 € on amazon), that I fixed with thermal epoxy from artic silver.

than I only needed a minuscule amount of thermal paste on the die (it is very tiny) and now I am very happy with the results.

In case anyone is interested I posted the little photos I made on the way.

A little Warning upfront: I was very nervous with the installation and especially the keyboard connector is VERY finicky. So only attempt this, if you have some experience with disassembling small integrated electronics.

There are a few videos out concerning the pretty bad thermal solution on the GPD WIN Rev 1, which was using one of those soft thermal pads to bridge the gap between the Atom SoC and the Copper of the Cooling Plate. It was causing the CPU to clock down pretty fast when using on full load.

I had not heard much about the solution used on the Rev 2, only that it was supposed to be a little better.

I can confirm that with a yes and a no. I am sorry to not have taken a picture, but I was probably just taken aback. They simply got rid of the soft thermal pad by using a 1,5 mm thick layer of thermal paste (the artic silver kind). I needed a few minutes to clean that off first...

To not shorten half the board in case it gets somewhere else than on the die, the did use silicon to cover nearby electronics so it kind of works I guess. But I think this is still not such a good way to dissipate the heat.

So I used the same method as by Phawx on his youtube guide, by using a 15x15x0,5 mm copper shimming plate (you can get a pack of those for 6 € on amazon), that I fixed with thermal epoxy from artic silver.

than I only needed a minuscule amount of thermal paste on the die (it is very tiny) and now I am very happy with the results.

In case anyone is interested I posted the little photos I made on the way.