may88

Well-Known Member

Angled upwards?I'm going to try and make a right angle breakout board file, I expect that this may be better for lots of things, what do you guys think?

Would the weight of the cable then be a problem?

Angled upwards?I'm going to try and make a right angle breakout board file, I expect that this may be better for lots of things, what do you guys think?

I mean angle 90* to the side. OFC one would be able to flip it so it is pointing either direction. What you describe would probably require two boards to be soldered together.Angled upwards?

Would the weight of the cable then be a problem?

Thank for your tip!Try design spark...

I think about this, but I beware about USB sockets on the EXT port sides and even right shoulder button could be in the way (finger lay over it respectively).I'm going to try and make a right angle breakout board file, I expect that this may be better for lots of things, what do you guys think?

Yes, I do this for a living. EMC analysis of PCBs and other electronics devicesJuliano: nice work! You are obviously in this field professionally, or .. student?

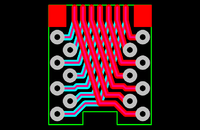

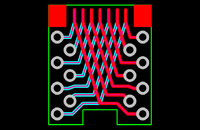

If you will allow me to make a couple of suggestions...OK, I managed to redesign PCB. Here it is (DesignSpark PCB file, gerber files, drill machine files and bmp export). No silk screen yet and I think it is stay as it is - board could be soldered upside down and then silk screen do bear service (as we say) - better to use brain for figuring signals out then blindly follow wrong silk screening.

tinyBoB.zip

View attachment 628